Versions

| No. | Features | Usage Scenario | Cloud Version | |

|---|---|---|---|---|

| Standard Version | Professional Version | |||

| 1 | Batch import data | Import cargo data by the Excel template batchly. | ✓ | ✓ |

| 2 | Simulate the interval | Simulate the phenomenon of box expansion or the gaps between cargoes in artificial placement | ✓ | ✓ |

| 3 | Single cargo and single container | Compute how many a container can load a kind of cargo, and restrict the length of every step of loading. | ✓ | ✓ |

| 4 | Single cargo and multiple container | Compute how many a kind of cargo can be packed in different containers. | ✓ | ✓ |

| 5 | Single cargo and multiple pallet | Compute how many a kind of cargo can be packed in different pallets. | × | ✓ |

| 6 | Multiple cargo and single container | Compute if a container / lorry can load all the given cargoes. | ✓ | ✓ |

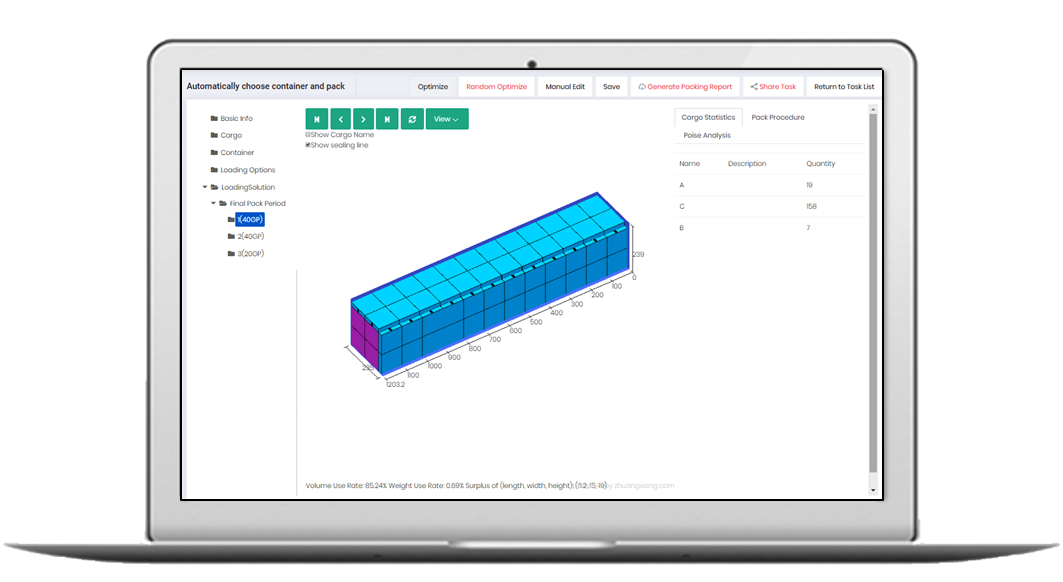

| 7 | Automatically choose container | Given some kinds of cargoes and containers, compute how to load the cargoes with containers. The container are chosen automatically. | ✓ | ✓ |

| 8 | Same cargoes packed together | The same cargo are packed together. | ✓ | ✓ |

| 9 | Sequence | Specify some cargoes should be loaded in a certain sequence. | ✓ | ✓ |

| 10 | Stacking Order | Set the stacking order according to the bearing capacity of cargoes and make sure that weighty cargoes are not on light cargoes. | ✓ | ✓ |

| 11 | Set Loading | The number of goods in a set should keep the quantity ratio. | ✓ | ✓ |

| 12 | Unit load | In the scenario of multiple cargoes and containers, pack the same cargoes in a single container as much as possible, if the volume usage rate exceeds a threshold. | ✓ | ✓ |

| 13 | Stack code | View the cargoes with the same stack code as a kind of cargo when computing layer number. | ✓ | ✓ |

| 14 | Cargo filling | Some cargoes are required to be filled in the container only when there is rest space after other cargoes were loaded over. | ✓ | ✓ |

| 15 | Container sequence | Select container with the specified contained sequence. | ✓ | ✓ |

| 16 | Minimum cost | Optimize plans with the object of minimizing cost. | ✓ | ✓ |

| 17 | Recomputing | Fix some containers and recalculate other containers. | ✓ | ✓ |

| 18 | Gravity balance 1 | When cargoes cannot fill all space in container, make them bottom spread. | ✓ | ✓ |

| 19 | Gravity balance 2 | Manually edit plan to ensure gravity center balance. | ✓ | ✓ |

| 20 | Gravity balance 3 | Gravity center analysis for railway containers and output 2D view. | ✓ | ✓ |

| 21 | Manual edit | Manually edit plans | ✓ | ✓ |

| 22 | Cargo database | Save cargo data in database for future usage. | ✓ | ✓ |

| 23 | Container database | Save container data in database for future usage. | ✓ | ✓ |

| 24 | Setting | Save the settings for future usage. | ✓ | ✓ |

| 25 | Prefer stand | The cargoes should be placed as "stand" with priority, and when there is space on the top, cargoes can be placed as "lay" with 1~2 layers. | ✓ | ✓ |

| 26 | Stack only when cargoes has the same length and width | Allow the cargo stack with cargoes with the same length and width. | × | ✓ |

| 27 | Group | Cargoes in the same order must be packed together and cannot be splitted into different containers. | × | ✓ |

| 28 | Platform lorry | Compute the lorry with high and low platform load cargoes | × | ✓ |

| 29 | Multiple cargoes on pallet | Allow the cargo in the same group mix with each other only. Allow the cargo exceeds the margin of pallet. | × | ✓ |

| 30 | All into pallet and then into container 1 | All cargoes are palletized first and then into container. The high and low pallet should be generated to make full use of the container space. | × | ✓ |

| 31 | All into pallet and then into container 2 | All cargoes are palletized first and then into container. And the unit load pallet should be generated with priority to decrease the quantity of mixed pallet. | × | ✓ |

| 32 | All into pallet and then into container 3 | All cargoes are palletized first and then into container. And the few remaining items are allowed to fill in the remaining space of the container directly. | × | ✓ |

| 33 | Part into pallet and then into container 1 | Partial cargoes are palletized and loaded into container with the other loose items. Some cargoes should be packed into a designated container type. | × | ✓ |

| 34 | Part into pallet and then into container 2 | Specify the pallet method of unit load. When there is less than one full pallet, specify the processing method of remaining goods. And then load them into the container. | × | ✓ |

| 35 | 3D display | Display 3D images and 2D images from every directions of load plans. Display the load details of every packing step. | ✓ | ✓ |

| 36 | Plan export | Export load plan to Excel and guide the on-site operation. | × | × |

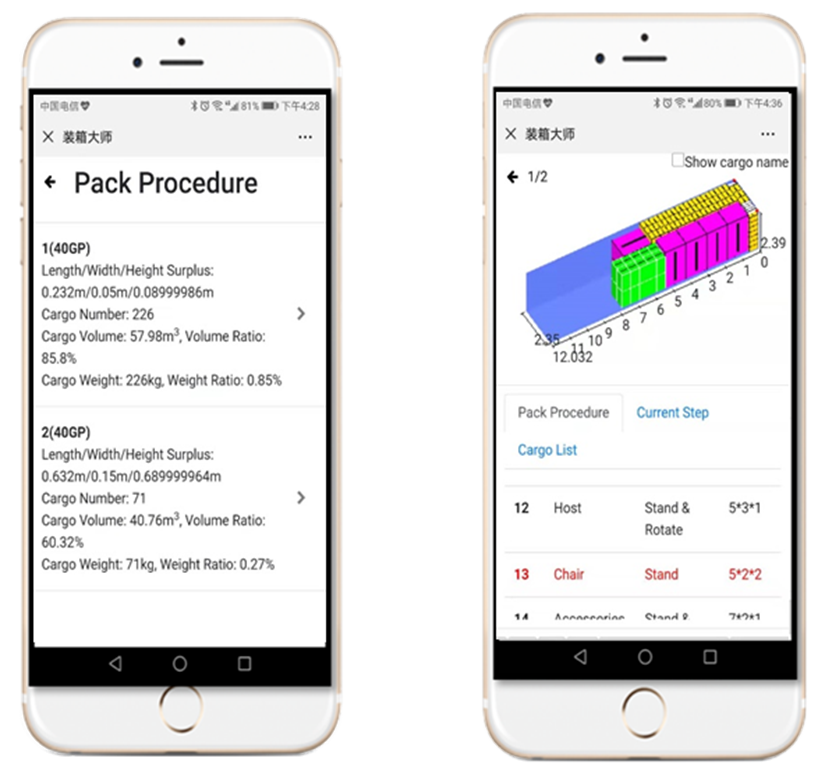

| 37 | Show plan on mobile platform | Scan QR code by mobile phone to get load plan and guide the on-site operation. Share load plan to customers and colleague. | ✓ | ✓ |

| 38 | Cargo Trace | Trace where the cargo are packed on mobile phone quickly, which facilitates customs inspection and increases customs clearance speed. | ✓ | ✓ |

| 39 | Data share | Save data in centralized database. Set access permission for every users. | ✓ | ✓ |

| 40 | Data integration | Integrate with current ERP/WMS and exchange cargo data / container data / load plans. | ✓ | ✓ |

| 41 | System integration | Integrate with systems to use the service of LoadMaster. | × | ✓ |

1-41 of 41

Feature Introduction

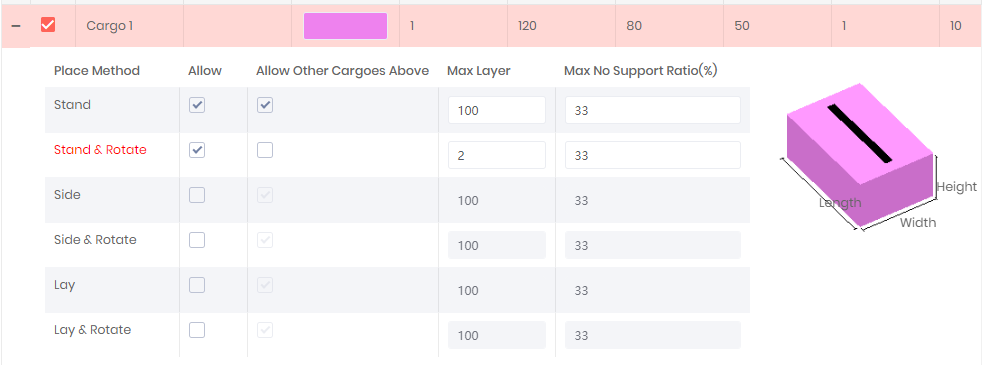

Basic Placement Constrain

● Every cargo has its own attributes

● Load orientations, max stack layers and max overhang ratio

● Every cargo's max stack layers are different in different load orientations. "Support Others" can be set or not set for different load orientations.

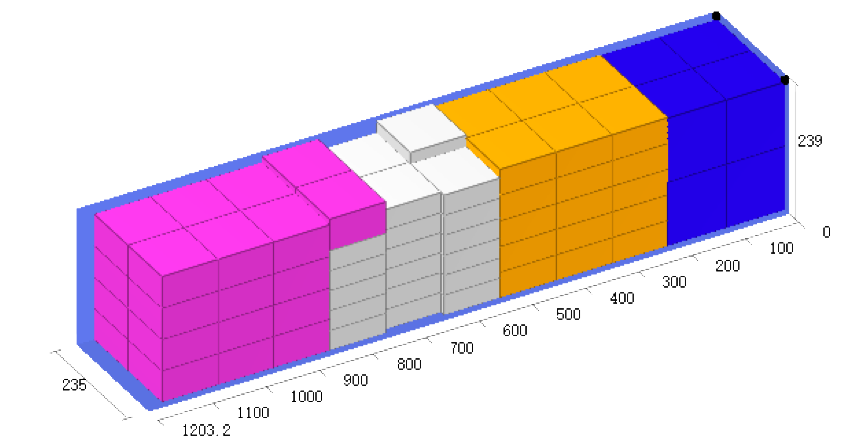

Same Items Together

● In practice, same cargoes are usually packed together, and we usually allow partial mixing between different items, which is convenient for operation and improves the volume use rate.

● Setting 1: check "Place the same cargoes next to each other"

● Setting 2: set "Cross Depth" to restrict the allowed mixing size when crossing

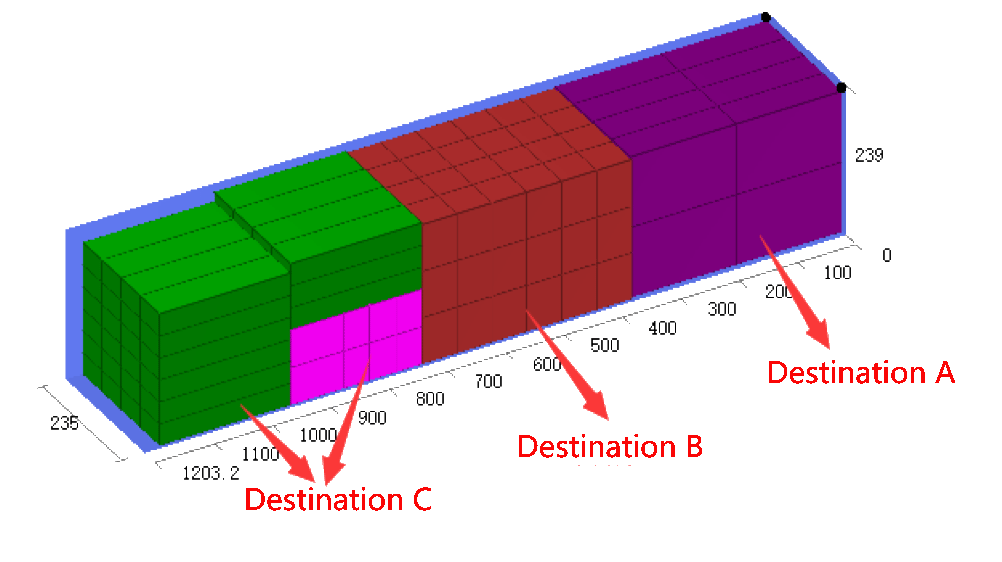

Loading Sequence

● Cargoes' loading sequence should be specified when they are from different warehouse or be sent to different destinations

● Setting 1: set the "Loading Sequence" of the cargoes

● Setting 2: Set the "Cross Depth" to restrict the allowed mixing size when crossing.

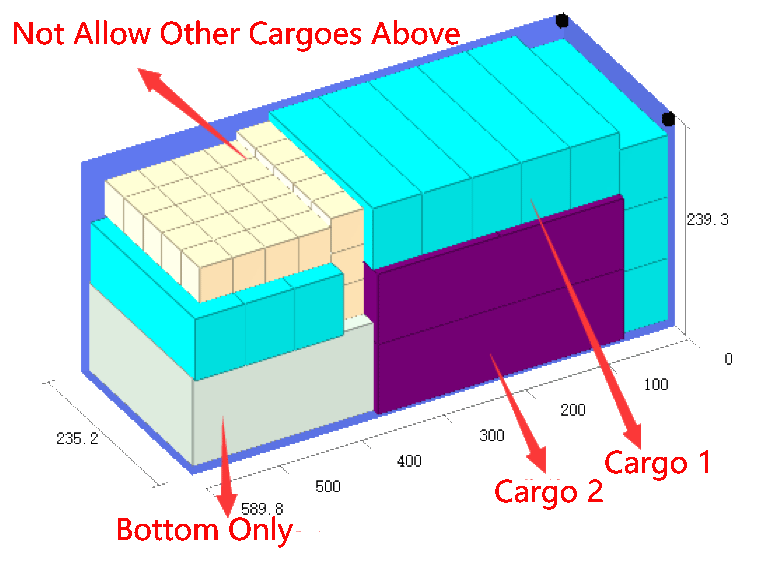

Stacking Order

● Due to the different bearing capacities of different cargoes, the cargo have the "Stacking Order" attribute. Cargo 2 has higher stacking order so cargo 2 is under cargo 1.

● For very large or very weighty cargoes, set "Bottom Only".

● For cargoes which are afraid of pressure, unset "Support Others"

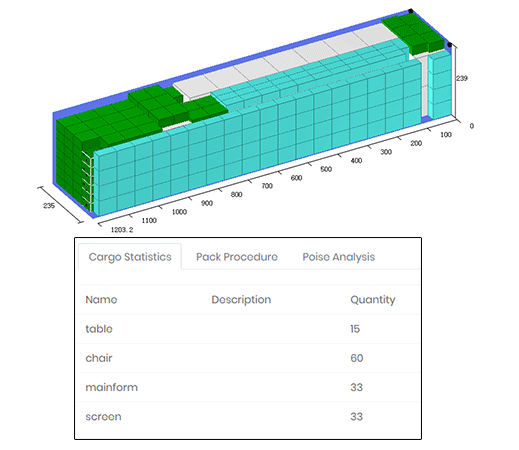

Set Loading

● The set cargoes are split into multiple boxes but must be loaded in complete suite, or the different products need to be loaded in proportion.

● For example, a computer is composed of a screen and a mainframe, and a suite of furniture is composed of a table and 4 chairs. Load plans must keep the ratio 1:1 and 1:4 respectively.

● In the result, a container can load 15 computers and 33 suites of furnitures

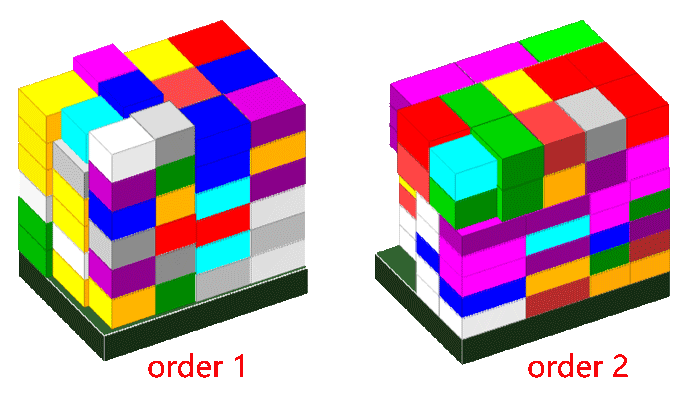

Cargo Group

● Sometimes only cargoes from the same order or with the same destination can be mixed.

● Unset the rule "Allow different groups of cargoes to be mixed in one container"

● In the example, cargoes in order 1 and order 2 are not mixed.

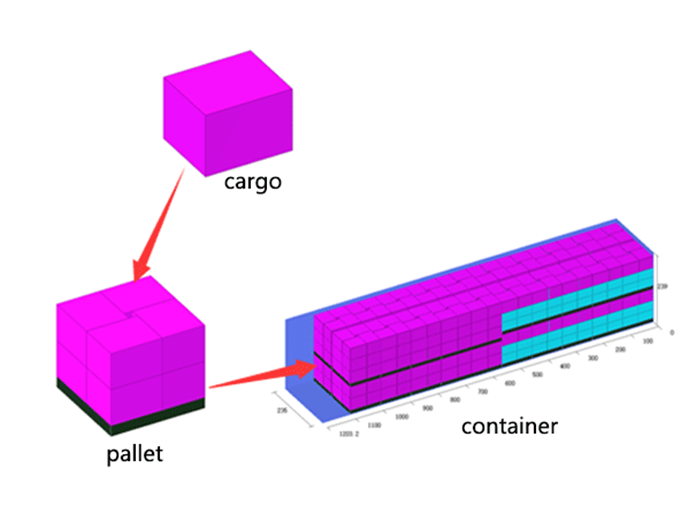

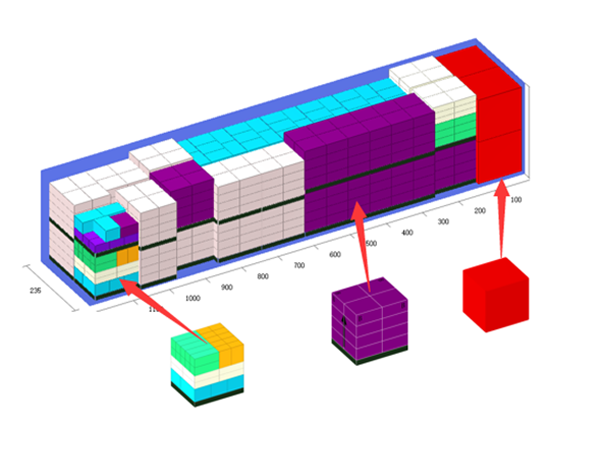

Two-step Packing

● All cargoes are packed in pallets, then pallets are packed in containers

● Some cargoes are packed in pallets, then pallets and other cargoes are packed simultaneously.

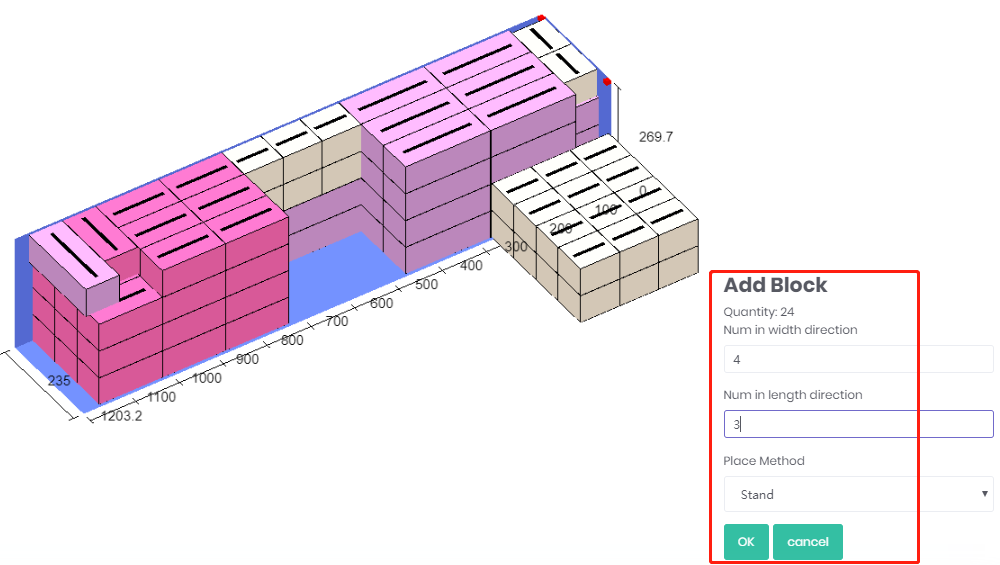

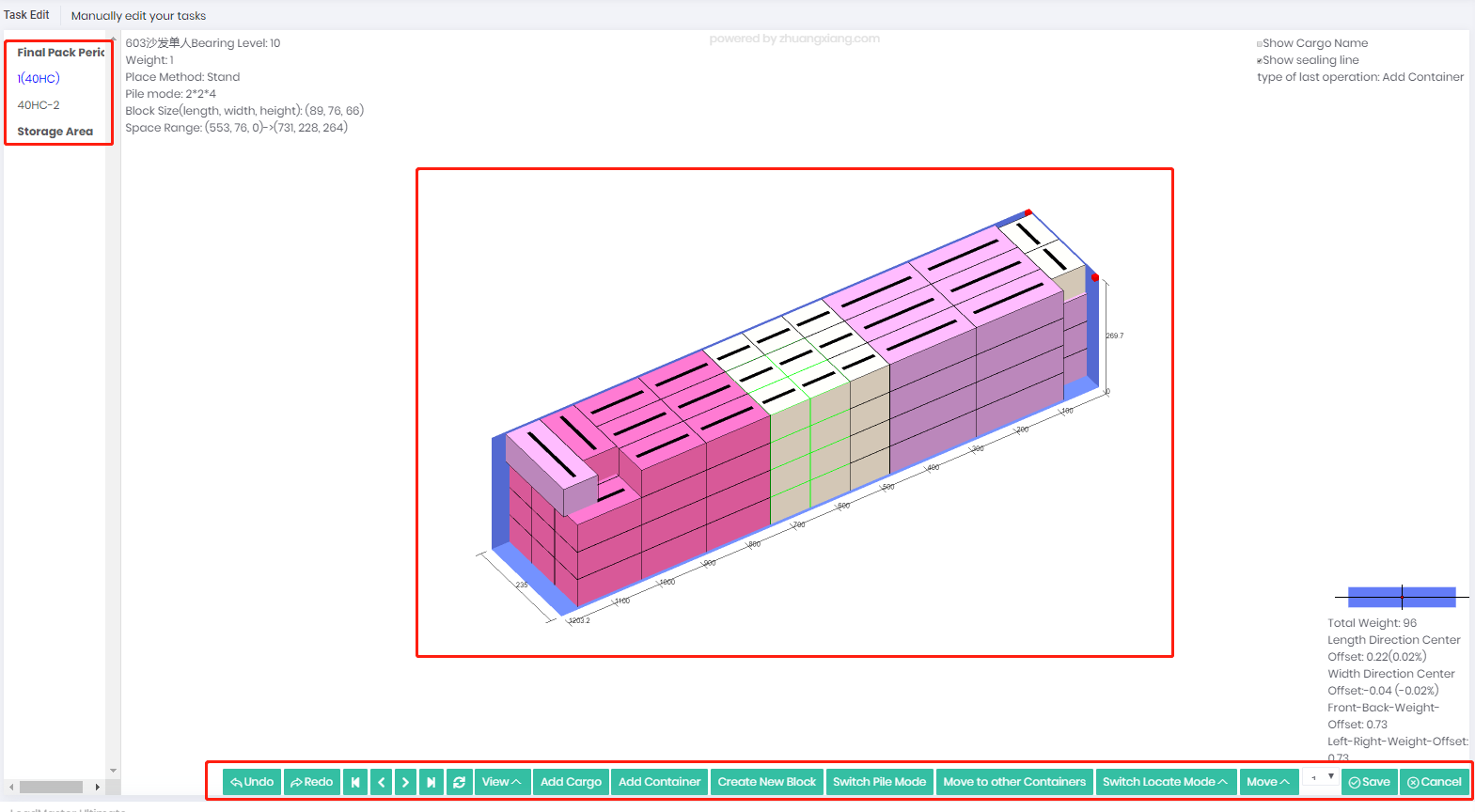

Manual Edit

Change the location and layout of cargoes, or move cargoes between different containers. Display real-time weight usage rate and views of gravity center.

LoadMaster Cloud Service

Safety

● We use the industry encrypt standard https and ensure security and reliability of data transmission.

● We build our service based on the Alibaba Cloud with high reliability.

● Your data was protected using the standard encryption.

Convenience

● LoadMaster Cloud Service doesn't require installation and you can access it anywhere as well as you can visit the Internet.

● LoadMaster is suitable for various working scene.

● Automatically upgrade without patch installation

Usage in Mobile platform

● Show load plans in mobile platforms anywhere.

● Paperless load plans can guide on-site operation.

● Share load plans with a keystroke and break the information barrier between different departments.